Cockpit Window Dock

Vor über einem Jahr erhielten wir von einem unserer langjährigen Partner – seit mehr als 20 Jahren Kunde – die Anfrage, ein universelles Dock für den Austausch von Cockpitfenstern zu entwickeln, geeignet für ihre gesamte Flotte von Narrow- und Widebody-Flugzeugen.

Das Dock sollte nicht nur für verschiedene Flugzeugtypen geeignet sein, sondern auch leicht zu manövrieren. Selbstverständlich galten unsere Standardanforderungen: robust, stabil, sicher und vollständig konform mit den Arbeitsschutzrichtlinien. Genau deshalb haben sie sich für Custers entschieden.

Von der Konstruktion bis zur Realisierung

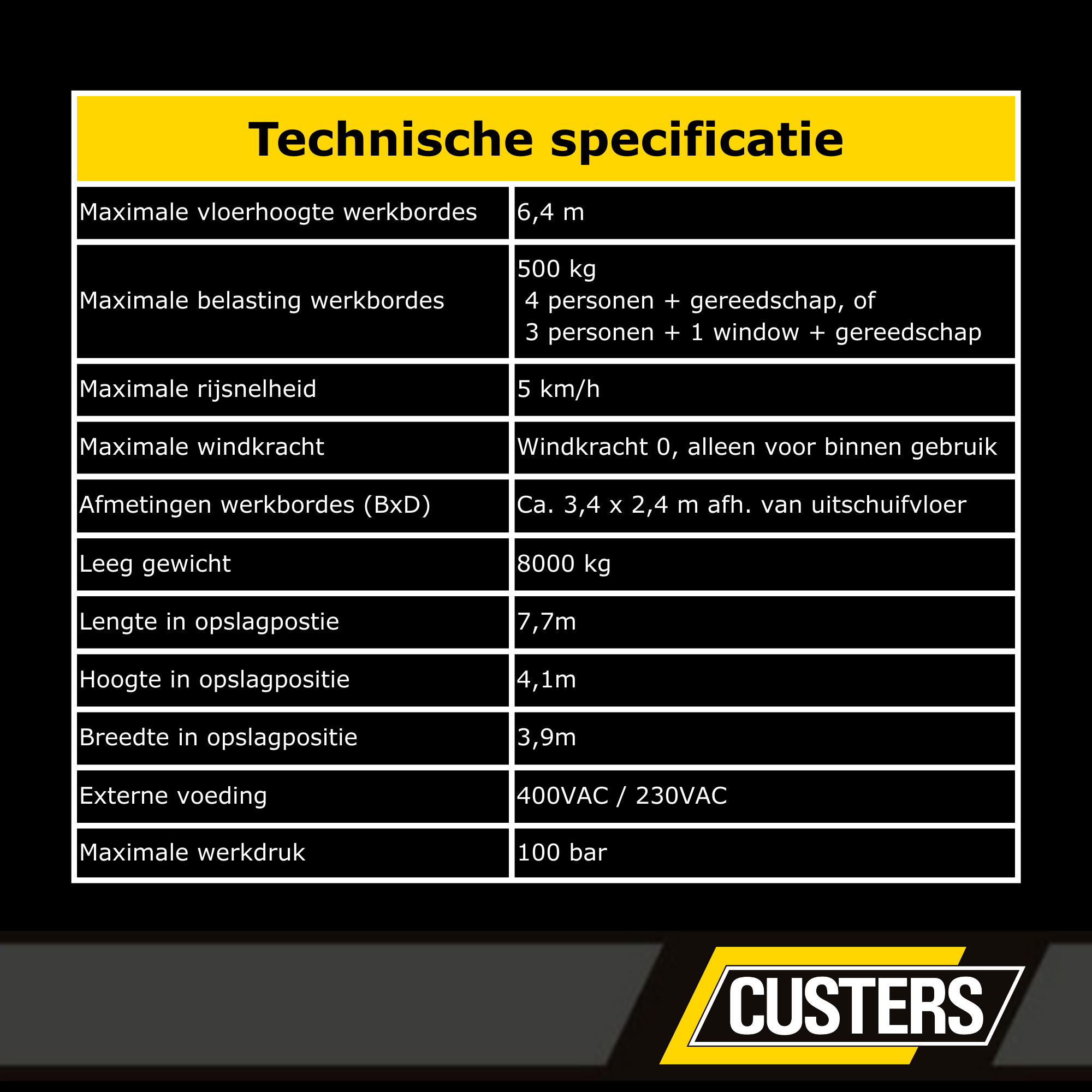

Unsere Ingenieure machten sich an die Arbeit und entwickelten das Cockpit Window Dock/Nose Dock: ein höhenverstellbares, mobiles Arbeitsbord für den Austausch von Cockpitfenstern, das für mehrere Flugzeugtypen einsetzbar ist. Nach Freigabe der Zeichnungen ging das Dock in die Produktion.

Test und Auslieferung

Nach der Fertigung fand in unserem Werk in Venray der Factory Acceptance Test (FAT) statt, bei dem Funktionalität und Sicherheit umfassend geprüft wurden.

Besonders begeistert waren sie von dem Kran auf dem Arbeitsbord, mit dem das Cockpitfenster direkt vom Hangarboden in Position gehoben werden kann.

Auslieferung

Anschließend wurde das Dock nach Schiphol geliefert, wo im Hangar die Site Acceptance Test (SAT) durchgeführt wurde. Dabei wurden alle Funktionen des Docks am Flugzeug getestet. Auch hier bestand das Dock mit Bravour.

Unser Kunde ist äußerst zufrieden mit dieser Lösung – ein schönes Beispiel für maßgeschneiderte Lösungen und erfolgreiche Zusammenarbeit!